|

|

Further Information

How to order:

Specification:

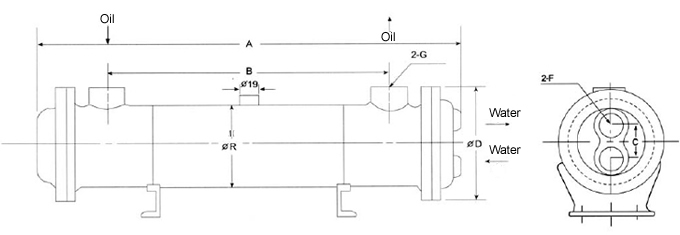

Dimension figure:

Overview and Selected:

Hydraulic piping in the oil, because of its inter-wall friction and the friction between the oil and the heat generated is the oil temperature rise, generally confined to the oil system of hydraulic oil 55 degrees, above this temperature , due to lower viscosity to increase oil leakage, valve performance, reduced the efficiency of the pump also fell, the oil deterioration and other issues also will be born, in order to prevent the above disadvantages, so use the coolers.。

The current product range includes: 1.KMLC series of oil cooler is the general structure of bare-tube cooling tube is made for possession of a few more densely arranged, heat dissipation is best. 2.HT series of oil cooler is attached to iron plates of the cooling pipe structure is made to increase the cooling area, so that cooler miniaturization. 3.HH series oil cooler is the general structure of bare-tube cooling tube made, easy to clean, for general use by the Qing-type cooler 4.DT oil cooler is a tooth-type cooling tube formed by rolling, get out of the tooth surface, heat larger 1、Heat exchange capacity Q Heat is greater than the amount of heat, a difference of heat if the cooler can be used to prevent the oil temperature rise, this is called the amount of heat exchange cooler Q, chosen based on this Q coolers, marked as used in the calculation in Table A Q=(T1-T2)*60*O.85*0.45*WS=(t2-t1)*60*1*1*Wt 2、Cooling water outlet temperature t2 (℃) Relative to the cooling water outlet temperature of the cooling water flow rate of oil: the cooling water = 1:0.5 ~ 1 (note) at this time of the cooling water flow rate (cooling water piping inside and out flow) shall be 0.5 ~ 1.5m / s range of t2 = Q/60 * WT + t1 (℃). 3、The average temperature difference △ tm (℃) For moving oil and cooling water export, import temperature difference as the base, and seek logarithmic mean temperature difference △ tm. Logarithmic mean temperature Do dynamic oil T1 → T2 Cooling water t2 → t1 △ t1 = T1-t2, △ t2 = T2-t1 By the type △ t1 and △ t2, corrections are as follows: From Table B the desired logarithmic mean temperature difference △ t'm, multiplied by the correction factor of X, X as shown below, obtained from Table C (t2-t1)/(T1-t1)=Y(T1-T2)/(t2-t1)=Z △tm=△t'm*X。 Note: The correction factor of demand and capacity from temperature efficiency ratio, as shown in Table C. 4、 Heat transfer area A A=Q/(△tm*K)。 5、All in all heat transfer coefficient K K values depending on the cooling water 'hydraulic oil viscosity varies, usually K = 200 ~ 650Kcal / m□ ℃ * h, KOMPASS multi-tube cooler, K = 350 ~ 500Kcal / m□ ℃ * h 1 / K = d1 / (d2hr) +1 / hs + rs. 6、By the motor output power, calculate the necessary exchange of heat heat E (Kcal / hr) = output power W (KW) * 860 (Kcal / hr * KW) to exchange the necessary heat Q (Kcal / hr) = Ex & prop ; α: Heat exchange coefficient general machinery without heat by taking 0.4 ~ 0.6 plastic machinery, die-casting machinery, there are those who take the heat source of 0.6 ~ 0.8. |

|

Service time:From Mon to Sat:8:30~17:30 Hotline:0086-21-67247466 86-13857458307 Fax:0086-21-67247499 MSN:jackshawpw@hotmail.com Skype:Jackbedra EMAIL:service@kuking.tw Copyright(C) 2000-2009 Shanghai KukingMachinery Co.,Ltd Kuking Group Co.,LTD All Rights Reserved |

沪ICP备07006861号 |

Remarks:

Remarks: